What is Supply Chain Management Companies and How Do They Operate?

Supply chain management companies play a crucial role in today’s global economy. Effective management in this sector ensures products reach consumers efficiently. As John Smith, a renowned expert in supply chain management, states, “The future of business relies on how well we manage our supply chains.” This highlights the importance of these companies in operational success.

In an era of rapid change, supply chain management companies face numerous challenges. They must adapt to market demands while navigating international logistics. Integrating technology is essential, yet many businesses struggle to keep pace. The constant need for optimization invites reflection on existing processes.

Moreover, these companies must prioritize sustainability. Finding eco-friendly solutions is not just a trend; it’s a necessity. Customers increasingly prefer companies that demonstrate environmental responsibility. This shift in consumer behavior urges supply chain management companies to rethink their strategies for a sustainable future.

What is Supply Chain Management? Definition and Key Concepts

Supply Chain Management (SCM) focuses on coordinating and optimizing all activities involved in the flow of goods. It encompasses planning, sourcing, producing, and delivering products to consumers. An efficient supply chain minimizes costs and enhances customer satisfaction. Companies that excel in SCM often observe significant reductions in lead times and waste.

Key concepts in SCM include demand forecasting, inventory management, and supplier relationships. Demand forecasting helps businesses predict customer needs accurately. This process informs inventory decisions and ensures products are available when required. Building strong relationships with suppliers can lead to better pricing and reliable deliveries. However, reliance on a few suppliers can backfire, especially during disruptions.

Challenges also abound in SCM. Unexpected events, like natural disasters or trade disputes, can disrupt supply chains. Companies must remain agile and responsive to adapt to these changes. Continuous evaluation and improvement are crucial. Many organizations struggle to align their supply chain strategies with overall business goals. This misalignment can lead to inefficiencies and missed opportunities.

What is Supply Chain Management Companies and How Do They Operate?

| Dimension | Description | Key Activity | Outcome |

|---|---|---|---|

| Procurement | Sourcing raw materials and services. | Supplier selection and negotiation. | Cost-effective and quality input materials. |

| Production | Transforming inputs into products. | Manufacturing process management. | Efficient and timely production. |

| Logistics | Transportation and warehousing of goods. | Managing distribution channels. | Timely delivery and reduced shipping costs. |

| Inventory Management | Overseeing stock levels and inventory turnover. | Stock replenishment and forecasting. | Minimized holding costs and stock-outs. |

| Customer Relationship Management | Managing interactions with customers. | Gathering customer feedback and analytics. | Improved customer satisfaction and loyalty. |

The Role of Supply Chain Management in Business Operations

Supply chain management (SCM) plays a pivotal role in business operations. It involves the oversight of materials, information, and finances as they move from supplier to manufacturer to retailer. According to a report by Statista, effective supply chain management can increase profitability by up to 20%. Companies that prioritize SCM experience improved efficiency and reduced operational costs.

One key aspect of SCM is collaboration among all stakeholders. This means suppliers, manufacturers, and distributors need to communicate effectively. However, many organizations struggle with this aspect. A report by the Council of Supply Chain Management Professionals (CSCMP) found that over 60% of businesses face challenges in supply chain visibility. Enhancing transparency can lead to better decision-making and faster response times.

Tips: Prioritize communication tools that facilitate real-time data sharing. Allocate time for regular meetings between teams. Frequent updates can prevent misunderstandings.

Moreover, digital transformation in SCM has become essential. Technologies such as AI and IoT are reshaping traditional processes. Yet, many companies hesitate to adopt these tools. Research from McKinsey reveals that 70% of digital transformations fail due to insufficient talent and resources. Companies should reflect on their current strategies and invest in training to leverage new technologies effectively.

Tips: Evaluate current skills within your team. Focus on continuous learning for all employees. Adapting to technology is crucial for future success.

Supply Chain Management: Operational Efficiency by Sector

Key Components of Supply Chain Management: Processes and Functions

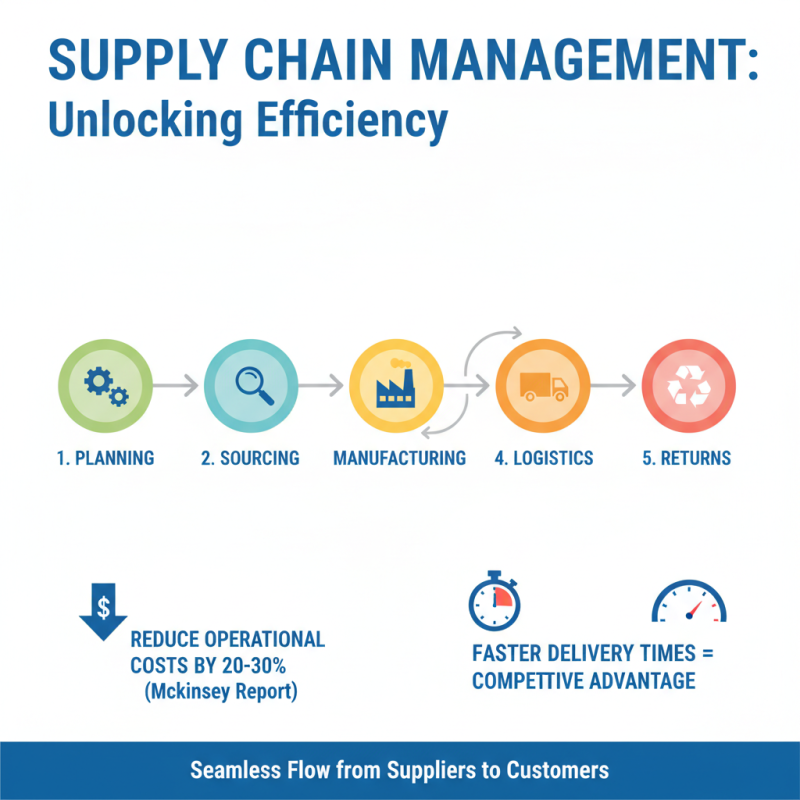

Supply chain management (SCM) is crucial for a company's efficiency. It integrates various operations to create a seamless flow from suppliers to customers. Key components include planning, sourcing, manufacturing, logistics, and returning products. According to a McKinsey report, companies that excel in SCM can reduce operational costs by 20-30%. This efficiency can lead to faster delivery times, which is vital in a competitive market.

Processes within SCM are interconnected. Proper planning ensures resources are allocated effectively. Sourcing focuses on acquiring quality materials at the best price. Manufacturing converts these materials into finished goods. Logistics is responsible for transportation and warehousing. Research indicates that poor logistics can inflate costs by 15% or more. Companies often struggle with these components, leading to inefficiencies.

Return processes are equally important. Defective products must be processed swiftly to maintain customer satisfaction. In fact, a study by Gartner notes that companies with excellent return strategies experience higher customer loyalty. However, many firms neglect this aspect, leaving room for improvement. Overall, while SCM has great potential, execution often reveals gaps that need addressing.

Industry Statistics: Impact of Effective Supply Chain Management

Effective supply chain management (SCM) significantly impacts various industries. Companies that focus on optimizing their supply chains often see improved efficiency. Statistics suggest that effective SCM can reduce operational costs by up to 20%. This reduction allows businesses to invest in other vital areas.

Moreover, effective SCM enhances customer satisfaction. When products are delivered on time, customers are happier. Studies show that 79% of customers are likely to switch to a competitor after one poor delivery experience. This emphasizes the need for companies to constantly review their supply chain strategies. Gaps in communication, inventory shortages, or delays can quickly sour customer relationships.

However, the journey to effective SCM is not perfect. Many companies face challenges in labor shortages and demand fluctuations. These issues can lead to unexpected delays. Some organizations may hesitate to invest in new technologies that could streamline processes. The reluctance to adapt can hinder progress, leaving them behind more agile competitors. The road to better supply chain management requires constant reflection and adjustment.

Challenges and Trends in Modern Supply Chain Management

In modern supply chain management, companies face various challenges that test their adaptability. One significant issue is the ever-increasing demand for transparency. Consumers want to know the origins of their products. This expectation can pressure companies to provide detailed information. Yet, providing such transparency is complex and resource-intensive. Many firms struggle with the logistics of data collection and sharing.

Another challenge is the integration of technology. Emerging technologies like AI and blockchain promise efficiency and security. However, not all companies are equipped to implement these solutions. The cost of technology can be daunting. Moreover, the learning curve may inhibit progress. Many organizations still rely on traditional methods, which can hinder their competitiveness.

Sustainability is another critical trend shaping supply chains today. Companies are under scrutiny for their environmental impact. While many aim to lessen their carbon footprint, the journey is often fraught with obstacles. Sourcing sustainable materials can be more expensive. Balancing cost and sustainability remains a challenging endeavor for many suppliers. Adapting to these trends is essential, but it often requires a significant shift in thinking.

Related Posts

-

10 Essential Tips for Choosing the Right Logistics Partner for Your Business

-

2025 Top Logistics Business Trends and Digital Innovations to Watch

-

2025 How to Choose the Best Logistics Solutions for Your Business

-

How to Start a Successful Logistics Business in 2023 Tips and Strategies

-

How to Choose the Right Order Fulfillment Services for Your Business?

-

Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023